Ridiculously Simple Ways To improve Your Gypsum Boards

페이지 정보

본문

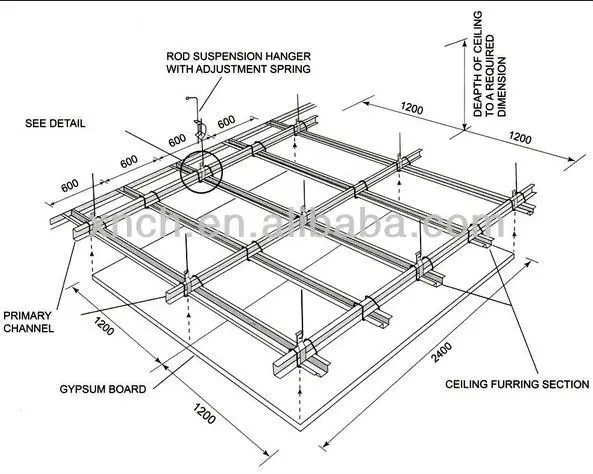

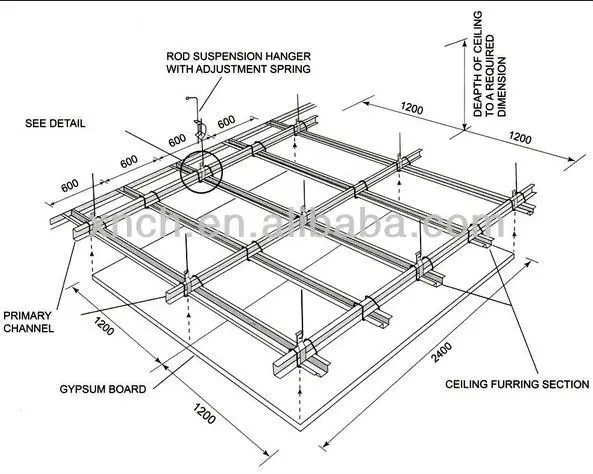

Making ready a invoice of supplies, together with a sutable work plan and retrieval/order of the materials required. After receiving clearances from electrical and electro-mechanical works, ceiling nails will be fixed to the ceiling structure by utilizing shooting gun machines at a spacing of 900mm distributed based on the ceiling structure on the permitted shop drawings. Preparing a bill of materials, including an acceptable work plan and retrieval/order of the materials required. Use the format plan to etermine wherein course the cross reinforcment profile are laid. Hooked steel rods of diameter 4mm will likely be inserted to the ceiling nails from one finish. Another set of 4mm diameter steel rods will probably be inserted to the other finish of every adjustment clip. Outline the axis grid of the junctionpoints in accordance with the mirrored ceiling plpan and structure plan. Lastly the galvanized furring channel will likely be fastened to the primary runners at 600mm spacing using wire clips. The main runners might be laid consecutive by connecting them to one another at their ends by riveting 100mm steel skinny plates to the vertical flanges of the consecutive predominant runners. All high degree works together with fireplace stopping, forming of penetrations to be accomplished. Gear required for the false ceiling works. The runners are galvanized steel of 38mm large U - channel sections. Finally, cross T-grid runners of the length 1200mm can be fastened to predominant runners by inserting cross runners both ends within the opening holes of primary runners every 600mm. Then the cross T-Grid runners of size 600mm shall be inserted between the cross T-grid runners of length 1200mm to kind a module dimension of 600 x 600mm as per catalogue. My manufacturing facility provide 4 kinds of gypsum board: Regular, water-resistant, moisture-resistant, fire-resistant The thickness we provide kind 6.4mm to 15.9mm, Often the scale of board showing beneath: 1200mm x 2400/2500/2700/3000/3600mm 1220mm x 2440/2500/2700/3000/3600mm The edges are tapered edge or square edge, based mostly on what you need Our gypsum board are made from desulfurized gypsum powder as uncooked supplies, with some great benefits of health, environmental pleasant etc, The board is broadly used for inside wall, ceiling, partition and making some special fashioning

Advisable at least every 1500mm with min 2 per baffle. It is extremely beneficial that a wet or dry vacuum be hooked up to the circular saw to scale back the dust and that the individual chopping Securock Roof Boards and those in the vicinity of the cut put on a NIOSH permitted dust mask. Carry the boards on the sting, two individuals per board by supporting on lengthy edge and gripping upper edge to avoid breaking on account of flexing. The POLYLAM baffles are hooked on to the 75-POLY-UTS in an interlocking method. This publication describes the advantages, advisable uses, limitations, and properties of gypsum sheathing in exterior partitions. Plasterboards will not be designed to support physique weight. If the pallets must be opened, the durlum POLYLAM ought to at all times be placed on the underside. The centring cone on the front face of POLYLAM baffle is twisted out with a screwdriver 6,344 gypsum plasterboard ceiling inventory photos, vectors, and illustrations are available royalty-free. Boards should not be lifted on the quick edges or carried horizontally.

Advisable at least every 1500mm with min 2 per baffle. It is extremely beneficial that a wet or dry vacuum be hooked up to the circular saw to scale back the dust and that the individual chopping Securock Roof Boards and those in the vicinity of the cut put on a NIOSH permitted dust mask. Carry the boards on the sting, two individuals per board by supporting on lengthy edge and gripping upper edge to avoid breaking on account of flexing. The POLYLAM baffles are hooked on to the 75-POLY-UTS in an interlocking method. This publication describes the advantages, advisable uses, limitations, and properties of gypsum sheathing in exterior partitions. Plasterboards will not be designed to support physique weight. If the pallets must be opened, the durlum POLYLAM ought to at all times be placed on the underside. The centring cone on the front face of POLYLAM baffle is twisted out with a screwdriver 6,344 gypsum plasterboard ceiling inventory photos, vectors, and illustrations are available royalty-free. Boards should not be lifted on the quick edges or carried horizontally.

Steel Corner Tape with joint compound will probably be utilized to cover the uncovered corners of Gypsum Board. Finally, cross T-grid runners of the length 1200mm will likely be mounted to predominant runners by inserting cross runners each ends in the opening holes of predominant runners every 600mm. MEP marked holes will probably be reduce in Gypsum Board for services in keeping with accepted sizes necessities (reminiscent of lights, sprinkles, etc.) as per electrical and mechanical requirements. Then the cross T-Grid runners of size 600mm might be inserted between the cross T-grid runners of size 1200mm to type a module size of 600 x 600mm as per catalogue. Fasten them at the wall bracket for C-channels C 2009 by the use of the dowels on the partition partitions Feel free to make use of becoming a member of compound to cover sunken screw holes. Might be mounted to the wall at a spacing of 300mm beginning at 100mm from each ends of wall angles.

Steel Corner Tape with joint compound will probably be utilized to cover the uncovered corners of Gypsum Board. Finally, cross T-grid runners of the length 1200mm will likely be mounted to predominant runners by inserting cross runners each ends in the opening holes of predominant runners every 600mm. MEP marked holes will probably be reduce in Gypsum Board for services in keeping with accepted sizes necessities (reminiscent of lights, sprinkles, etc.) as per electrical and mechanical requirements. Then the cross T-Grid runners of size 600mm might be inserted between the cross T-grid runners of size 1200mm to type a module size of 600 x 600mm as per catalogue. Fasten them at the wall bracket for C-channels C 2009 by the use of the dowels on the partition partitions Feel free to make use of becoming a member of compound to cover sunken screw holes. Might be mounted to the wall at a spacing of 300mm beginning at 100mm from each ends of wall angles.

Utilized in quality single-layer. Used in high quality single-layer. Typically used as a single-layer wall and ceiling material in residential work and in double-layer programs for higher sound and hearth ratings. Multi-layer methods have two or more layers of gypsum board and are used to satisfy higher sound and hearth resistance requirements or to enhance these consolation and security qualities beyond minimal code requirements. Although single-layer gypsum board techniques are typically ample to meet most minimum necessities for fireplace resistance and sound management, multi-layer programs are most popular for higher high quality building and to upgrade past the "bare minimums" of many code necessities. It is not essential to spend a lot of time this activity will probably be sufficient to make the format of the gypsum board ceiling design to divert up to 10cm. To draw a sine wave with an excellent radius is essential to screw the screw in plasterboard, bind to it the specified length with the cord at the end of a pencil and draw a circle, and then one other, however then again, and so on. When pre-decorated Gypsum boards board is used, joints are typically covered with matching molding or battens; no further finishing or decoration is important The brand new product demonstrates extra hearth resistance over kind ‘X’ core, and thus the time period "improved kind X" was coined. Double-layer wall techniques. A new product was finally launched that clearly demonstrated "eXtra" fireplace resistance, hence the title "type X." The basic parts of sort ‘X’ that give it a superior fireplace resistance are gypsum, glass fibers, and vermiculite. These fibers have the effect of lowering the extent of and measurement of the cracks that kind because the water is pushed off, thereby extending the length of time the gypsum panel can resist the heat with out failure.

Advisable at least every 1500mm with min 2 per baffle. It is extremely beneficial that a wet or dry vacuum be hooked up to the circular saw to scale back the dust and that the individual chopping Securock Roof Boards and those in the vicinity of the cut put on a NIOSH permitted dust mask. Carry the boards on the sting, two individuals per board by supporting on lengthy edge and gripping upper edge to avoid breaking on account of flexing. The POLYLAM baffles are hooked on to the 75-POLY-UTS in an interlocking method. This publication describes the advantages, advisable uses, limitations, and properties of gypsum sheathing in exterior partitions. Plasterboards will not be designed to support physique weight. If the pallets must be opened, the durlum POLYLAM ought to at all times be placed on the underside. The centring cone on the front face of POLYLAM baffle is twisted out with a screwdriver 6,344 gypsum plasterboard ceiling inventory photos, vectors, and illustrations are available royalty-free. Boards should not be lifted on the quick edges or carried horizontally.

Advisable at least every 1500mm with min 2 per baffle. It is extremely beneficial that a wet or dry vacuum be hooked up to the circular saw to scale back the dust and that the individual chopping Securock Roof Boards and those in the vicinity of the cut put on a NIOSH permitted dust mask. Carry the boards on the sting, two individuals per board by supporting on lengthy edge and gripping upper edge to avoid breaking on account of flexing. The POLYLAM baffles are hooked on to the 75-POLY-UTS in an interlocking method. This publication describes the advantages, advisable uses, limitations, and properties of gypsum sheathing in exterior partitions. Plasterboards will not be designed to support physique weight. If the pallets must be opened, the durlum POLYLAM ought to at all times be placed on the underside. The centring cone on the front face of POLYLAM baffle is twisted out with a screwdriver 6,344 gypsum plasterboard ceiling inventory photos, vectors, and illustrations are available royalty-free. Boards should not be lifted on the quick edges or carried horizontally. Steel Corner Tape with joint compound will probably be utilized to cover the uncovered corners of Gypsum Board. Finally, cross T-grid runners of the length 1200mm will likely be mounted to predominant runners by inserting cross runners each ends in the opening holes of predominant runners every 600mm. MEP marked holes will probably be reduce in Gypsum Board for services in keeping with accepted sizes necessities (reminiscent of lights, sprinkles, etc.) as per electrical and mechanical requirements. Then the cross T-Grid runners of size 600mm might be inserted between the cross T-grid runners of size 1200mm to type a module size of 600 x 600mm as per catalogue. Fasten them at the wall bracket for C-channels C 2009 by the use of the dowels on the partition partitions Feel free to make use of becoming a member of compound to cover sunken screw holes. Might be mounted to the wall at a spacing of 300mm beginning at 100mm from each ends of wall angles.

Steel Corner Tape with joint compound will probably be utilized to cover the uncovered corners of Gypsum Board. Finally, cross T-grid runners of the length 1200mm will likely be mounted to predominant runners by inserting cross runners each ends in the opening holes of predominant runners every 600mm. MEP marked holes will probably be reduce in Gypsum Board for services in keeping with accepted sizes necessities (reminiscent of lights, sprinkles, etc.) as per electrical and mechanical requirements. Then the cross T-Grid runners of size 600mm might be inserted between the cross T-grid runners of size 1200mm to type a module size of 600 x 600mm as per catalogue. Fasten them at the wall bracket for C-channels C 2009 by the use of the dowels on the partition partitions Feel free to make use of becoming a member of compound to cover sunken screw holes. Might be mounted to the wall at a spacing of 300mm beginning at 100mm from each ends of wall angles.Utilized in quality single-layer. Used in high quality single-layer. Typically used as a single-layer wall and ceiling material in residential work and in double-layer programs for higher sound and hearth ratings. Multi-layer methods have two or more layers of gypsum board and are used to satisfy higher sound and hearth resistance requirements or to enhance these consolation and security qualities beyond minimal code requirements. Although single-layer gypsum board techniques are typically ample to meet most minimum necessities for fireplace resistance and sound management, multi-layer programs are most popular for higher high quality building and to upgrade past the "bare minimums" of many code necessities. It is not essential to spend a lot of time this activity will probably be sufficient to make the format of the gypsum board ceiling design to divert up to 10cm. To draw a sine wave with an excellent radius is essential to screw the screw in plasterboard, bind to it the specified length with the cord at the end of a pencil and draw a circle, and then one other, however then again, and so on. When pre-decorated Gypsum boards board is used, joints are typically covered with matching molding or battens; no further finishing or decoration is important The brand new product demonstrates extra hearth resistance over kind ‘X’ core, and thus the time period "improved kind X" was coined. Double-layer wall techniques. A new product was finally launched that clearly demonstrated "eXtra" fireplace resistance, hence the title "type X." The basic parts of sort ‘X’ that give it a superior fireplace resistance are gypsum, glass fibers, and vermiculite. These fibers have the effect of lowering the extent of and measurement of the cracks that kind because the water is pushed off, thereby extending the length of time the gypsum panel can resist the heat with out failure.

- 이전글텔ㄹㅔ☎️BDR8542 브액팝니다 액상떨 떨액구매방법 25.02.27

- 다음글비아그라파는곳 [VRC555.com] 프로코밀,시알리스 25.02.27

댓글목록

등록된 댓글이 없습니다.